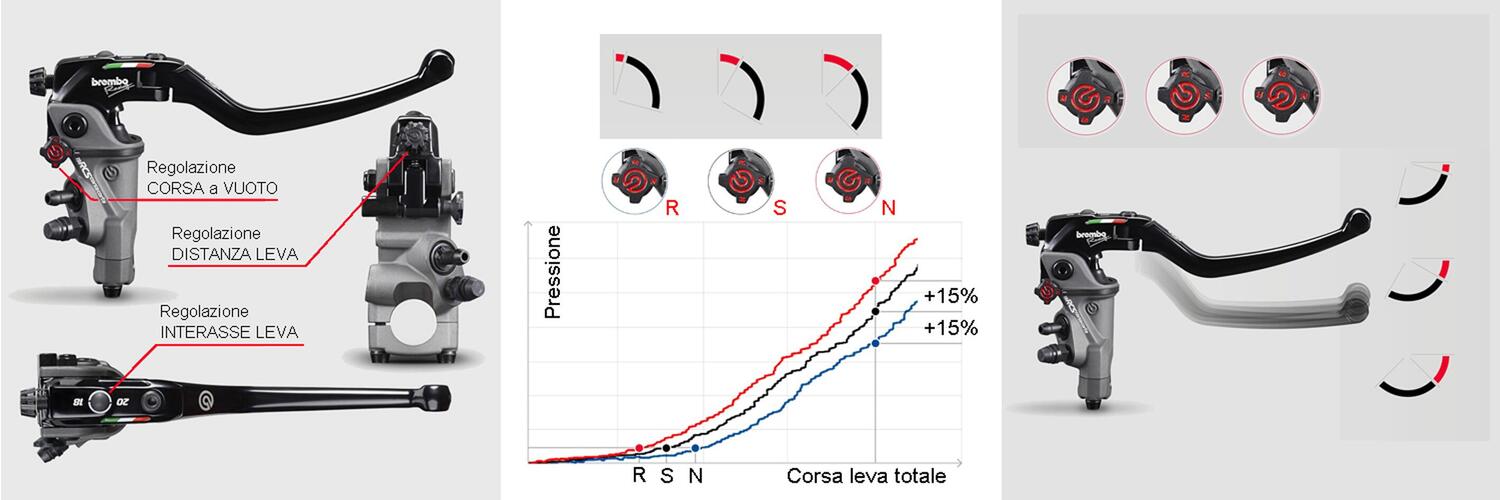

The idle stroke setting has been added to the two already existing setting possibilities: the adjustment of the distance of the lever from the handlebar and the RCS (Ratio Click System) system, which allows to select a fulcrum-to-piston distance, with two different positions: 18 mm, where the bite point starts more gradually, and 20 millimeters for an immediate response.

The play of a master cylinder consists in the movement of the piston from brake lever total release position to the closing of the master cylinder's reservoir feed hole. During this movement, the pressure in the braking circuit does not increase and, consequently, there will be no braking action. From the forward closing of the feed hole (effective stroke), the pressure in the braking circuit will increase until reaching the desired braking effect.

How big is this parameter? In relation to the type of product (Racing or OE master cylinder) and to the machining tolerances, the idle stroke can vary from a few tenths to 2 mm. How important is it? Although very small, it is a very important parameter: just think that in MotoGP the riders use master cylinders with calibrated and customized idle strokes, with variations of hundredths of a millimeter.

19 RCS Corsa Corta is full adjustable:

- BITE POINT (IDLE STROKE):

Three different Maps, R-S-N, the selector operates a cam mechanism to let the user choose between three different responsiveness settings. - LEVER POSITION:

Click by Click You can adjust the Distance of the Lever from the bar and adapt it to your hand or to your needs. - RCS (Ratio Click System):

Lets the rider select a fulcrum-to-piston distance of 18 or 20 mm by simply turning the adjuster screw on the front of the guide lever by 180° with a screwdriver.

The 19 RCS Corsa Corta is fully adjustable.

R position R “RACE” : the position of the cam mechanism shortens the initial stage of the bite point, immediate braking feedback even at the lever

S position S “SPORT” : the beginning of the bite point is shorter than in the N setting. This setting produces a more dynamic response suitable for sportier riding.

N position “NORMAL” : the bite point starts more gradually, the braking is smoother

Two-position calibration: adjustment of the lever centre-to-centre distance acts on the entire lever stroke, making braking more responsive (int. 20) or more modular (int. 18)

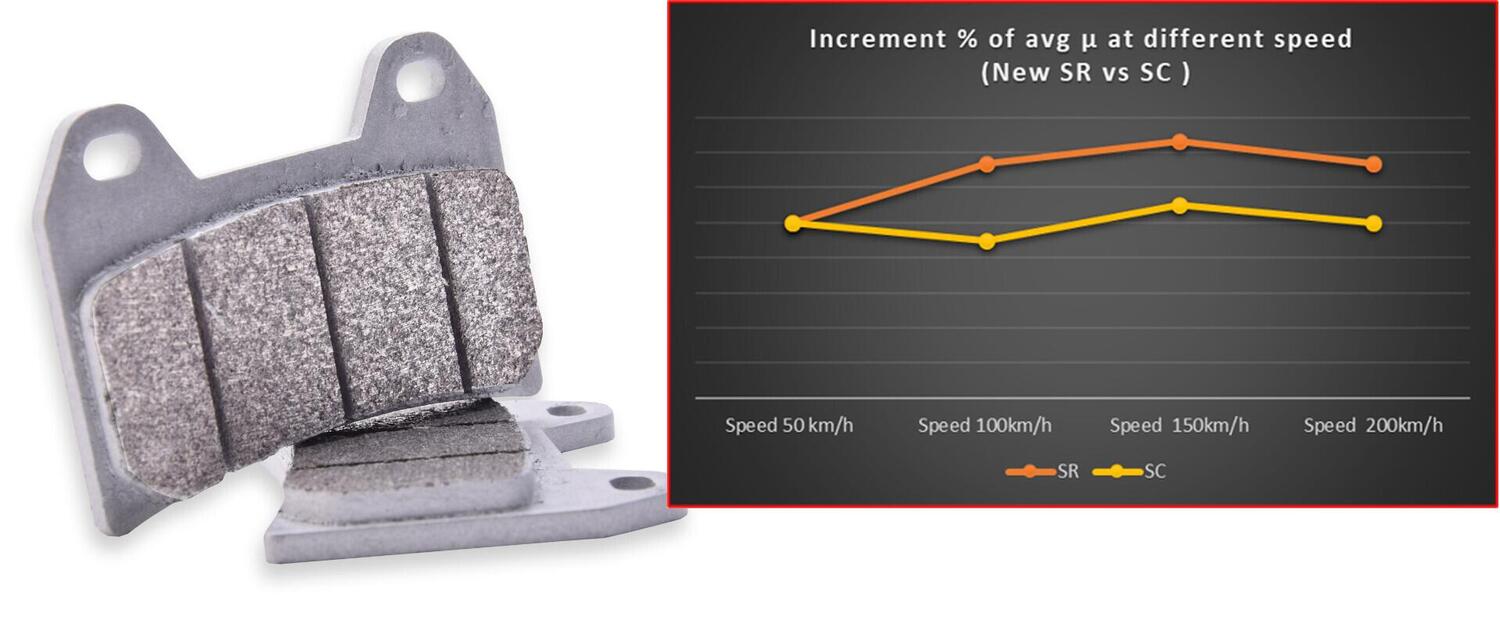

Pads designed for a specific use, with construction characteristics meant to provide high performance especially with high disc temperatures.

RC COMPOUND

A compound conceived solely for track use, a true racing pad with high friction and consistent efficiency, especially at high disc temperatures, ensuring a consistent braking for the entire duration of the race.

SR COMPOUND

A new compound by Brembo: this new compound enriches the range of Brembo's pads suitable for the needs of “aggressive” motorcyclists on the brake lever and looking for high-level performance. The SR is a pad for track use with a high and constant coefficient of friction at high temperatures. It's also usable on the road thanks to the excellent feeling and reduced wear: it is therefore the ideal choice for those who particularly stress the braking system in every condition.

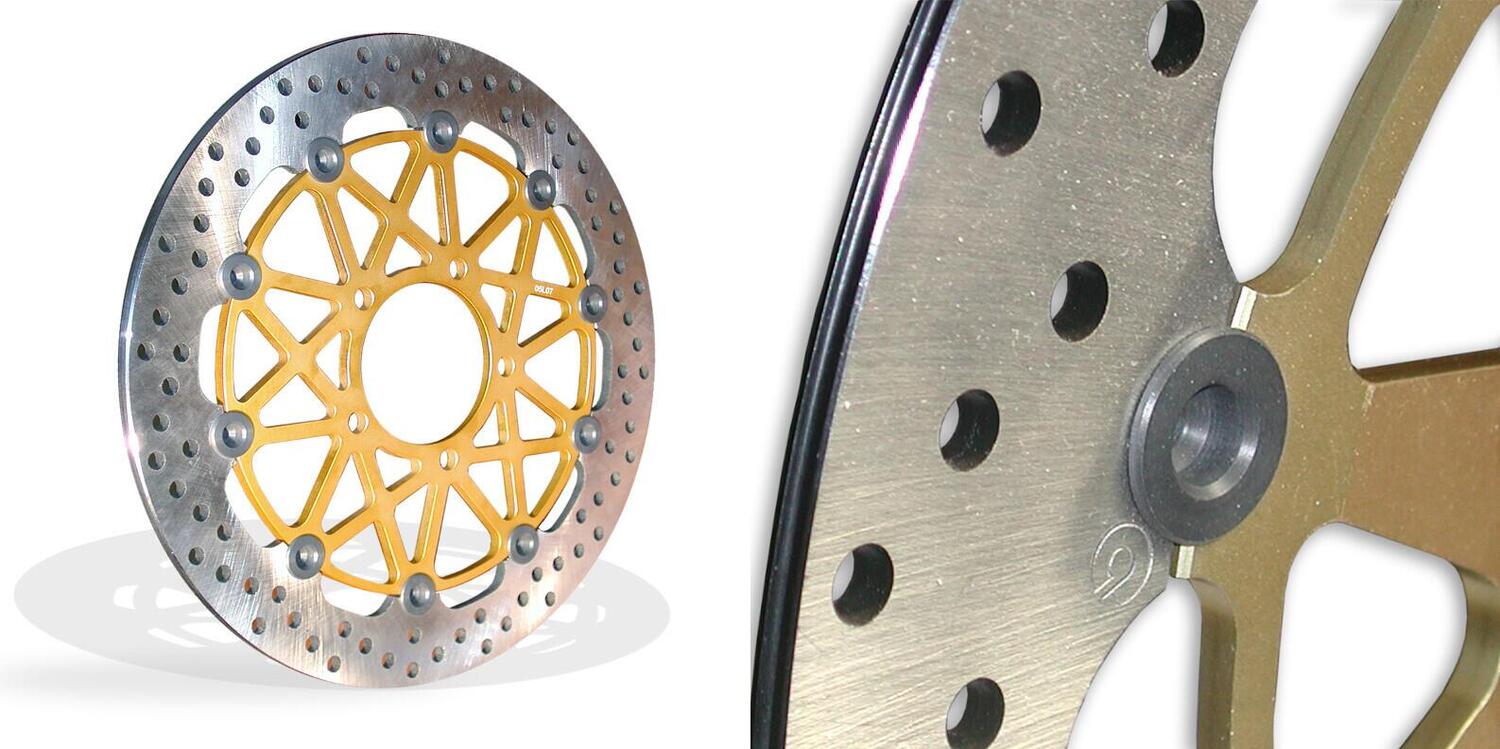

Used by almost all the riders of the WSS world championship, they are interchangeable with the original discs of the most popular SuperSport and Naked bikes, for all those riders who want components for their bike that combine performance and icon. In some cases, a version with a larger diameter than the standard disc is available to further increase braking power. Two versions: SuperSport with rotor in thermally treated steel and a housing machined from billet aluminium alloy and T-Drive, with drag derived from the experience of World SBK.

SUPERSPORT DISCS

Supersport discs, 5.5 mm in thickness, are fully interchangeable with the original components without any modifications, even with some Brembo Racing floating calipers.

These are fully floating discs consisting of a rotor in thermally treated steel (capable of resisting extreme thermo-mechanical stress) and a housing machined from billet aluminium alloy.

T-DRIVE DISCS

The range is extenfing with the T-DRIVE whose shape of the 8 “T” pins on the disc and the eight shapes on the braking torque dragging system, allows to transfers braking torque more effectively, providing improved resistance to thermo-mechanical stress.

The rotor - in steel identical to that used for the discs in SBK and MotoGP - has been improved by reducing the height to the advantage of containing weight and resulting in an improved handling and by a new differentiated diameter hole pattern. Even the bell has been made in a light alloy by CNC, allowing to save on some weight while increasing the rigidity.

PRODUCT DISTRIBUITED BY MOTORQUALITY S.P.A. – WWW.MQMOTO.IT